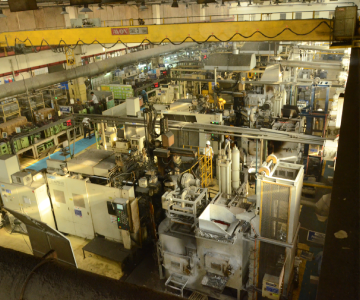

Manufacturing Facilities

Subros has established advanced manufacturing facilities strategically located across India to meet the diverse and growing demands of our customers.

of Excellence

These facilities are designed to deliver excellence through cutting-edge technology, streamlined operations, and a commitment to quality and innovation.

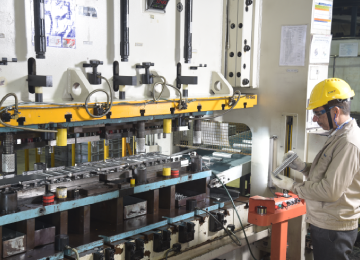

Compressor Plant, Noida

B 188 , Phase II, Gautam Budh Nagar, U.P. 201304

The compressor plant specializes in producing Fixed Displacement (Piston & Swash Type) and Vane type compressors catering to wide range of vehicle applications. Equipped with state-of-the-art CNC machines and advanced automatic testing equipment, the plant ensures precision, reliability, and unmatched quality in every compressor manufactured.

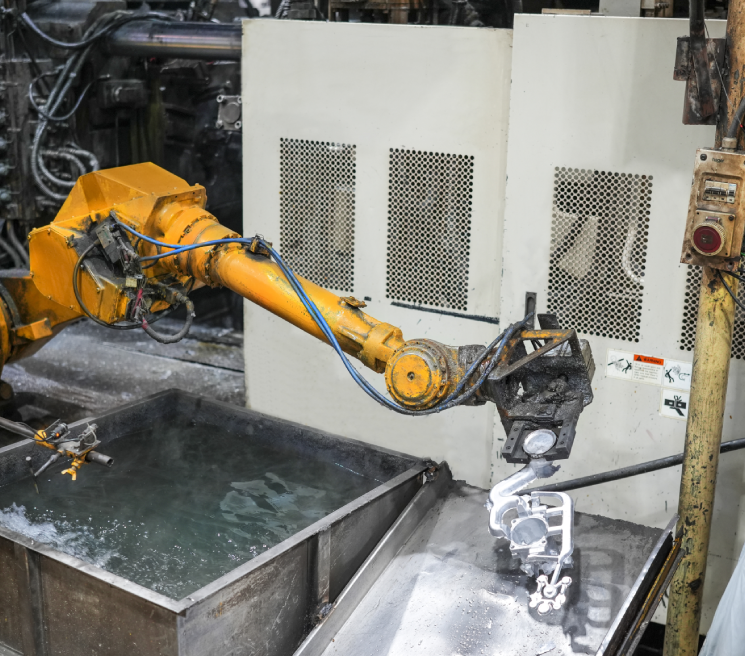

Die Casting Plant, Noida

B-216, Phase II, Noida, Gautam Budh Nagar, U.P. 201304

Subros is pioneering in squeeze die casting technology. Die Casting plant, capable of producing high-quality, intricate castings using advanced squeeze and vacuum die casting processes. This cutting-edge technology, ensures superior precision, strength, and durability in every casting, setting a benchmark in manufacturing excellence.

Heat Exchanger Plant, Noida

B-195, Phase II, Noida, Gautam Budh Nagar, U.P. 201304

Subros Advanced Heat Exchanger Manufacturing plant at Noida is equipped to produce state-of-the-art Brazed Multi-Flow Condensers, Heater Cores, and RS Evaporators. These components are crafted with precision and cutting-edge technology to meet the highest standards of performance and reliability for diverse automotive applications.

Manesar Plant

Plot No. 395-396, Sector-8, Phase III, IMT Manesar, Gurgaon 122050

Subros Manesar plant, located in close proximity to the Maruti Suzuki India Limited factory, spans an area of 38,000 square meters. This facility is equipped with the latest state-of-the-art manufacturing of HVAC, Condenser, Radiator, Hose and Tubes and testing equipment, ensuring high-quality production and operational efficiency.

Karsanpura Plant

Plot No. 508, 509, 512, 514, 516, 517, Village-Karsanpura, Vithlapur, Taluka-Madal, Ahmedabad, Gujrat 384335

Subros manufacturing facility at Karsanpura, Gujarat, is strategically situated near the Suzuki Motors Gujarat Hansalpur Plant, ensuring seamless operations and supply chain efficiency. Spanning an expansive 17-acre plot, this facility features technologically advanced manufacturing lines designed to deliver superior quality and performance.

In addition to its cutting-edge capabilities, the plant is equipped with best-in-class safety features, reflecting our unwavering commitment to employee welfare and operational excellence.

Chennai Plant

A-20/1 SIPCOT Industrial Growth Centre, Oragadam, Chennai 602105.

Our Chennai plant has been strategically established to serve customers in the southern region of India efficiently. This facility is dedicated to manufacturing a range of products, including air conditioning systems for the Commercial Vehicle segment, railways, and transport refrigeration systems. Additionally, the plant produces A/C parts to cater to Aftermarket requirements, ensuring comprehensive support for diverse customer needs.

Pune Plant

B-8 & 9, MIDC-Chakan Ind. Area, Chakan-Talegaon Road, Chakan, Pune 410501

Located in Chakan, Pune, our plant spans over 24,000 square meters and is strategically positioned close to our customer in western region enabling us to offer faster and more efficient service to our customers. The plant is equipped with the latest production technologies for car, bus and tractor applications.

Nalagarh Plant

150/2, Revenue Circle, Nalagarh, IIDC Nalagarh Village Theda, Solan, Himachal Pradesh - 173205

Subros Nalagarh facility is a fully integrated, state-of-the-art plant dedicated to the manufacturing and assembly of residential and commercial cooling products, including Window ACs, Split ACs, and commercial units. This advanced facility houses cutting-edge equipment such as Fin-Tube Type Heat Exchanger manufacturing, Fin Press, Expanders, Automatic Brazing Machines, Cross Flow Fan manufacturing, Plastic Moulding, and a Fully Automated Paint Shop, along with other specialized tools.

Backed by a strong design capability, the plant also features an in-house laboratory equipped to design and test complete products, ensuring they meet exacting customer requirements and industry standards.